Swarovski FAQ – Part 2

October 30, 2020

Jewellery for winter, Christmas and New Year’s Eve

November 26, 2020In Part 1, we discussed the use and application of HotFix and No HotFix crystals, Ceralun and Swarovski Crystal Mesh. In Part 2, we described the most popular Swarovski crystals and application with the use of glue and self-adhesive films. However, in this part we will focus on mechanical application, soldering, stone setting and crystals for sewing. In addition, we will answer few questions received from our customers regarding Swarovski crystals and pearls.

How to apply Swarovski crystals?

— continuation from previous article: Swarovski FAQ — Part 2

Many Swarovski products are suitable for applying manually or mechanically, using semi or fully automatic devices, which create a permanent bond between the product and the material. Examples include Rivets, Rose Pins, and 3D Studs, used in jewelry making, accessories and textile industry. For specific application, the appropriate arrangement of dies in relation to the product and material should be taken into account, as well as the space between the elements to prevent their damage. Additionally, the use of protective eyewear is recommended during mechanical application.

a) Swarovski Rivets.

Rivets are the perfect solution for extremely secure bonding, which can be used not only on jewelry, but also on belts, bags, shoes, or denim and leather garments. Rivets come in a variety of shapes and sizes, and can be used with, or without backs, on materials 1.5 mm to 3 mm thick. When applying on thinner fabrics, it is better to use larger backs, and for thick and multi-layer fabrics, use smaller backs. The offer includes round metal rivets decorated with shiny Xirius Chatons, Xilion Chatons, Cabochon Rivets, Xirius Rose Flat Backs, Square Rivets, as well as sharp and metallic glam-punk Spike Rivets, which have become a hit in rock fashion, decorating jeans, jackets, shoes, belts and collars. When selecting rivets, application method and equipment, it is important to check the thickness of the fabric and also to test in advance to adjust the pressure during application. In the case of very thick materials and leather or fabrics arranged in layers, it is worth punching a hole in advance to apply rivets, to avoid crinkling of the material. When using fly press, the appropriate combination of dies should be selected and seated straight and firm to the product in order to avoid problems with the application.

b) Swarovski Rose Pins.

Rose Pins consist of spectacular Xilion or Xirius crystals placed in hooks and glued underside to steel pins. The application is very simple and consists in punching the pins through the material, using a semi-automatic or fully automatic attaching machines with a vacuum pump, that allows easy picking up and placing of pins. Such an application system ensures a very safe and invisible grip. The product has increased durability and resistance to corrosion, therefore it is often used to decorate items, that are exposed to regular wear and tear. Examples include bags, clothing and even furniture. Pins combine functionality with the phenomenal shine of crystals, making them a favorite in the leather and footwear segment. The material thickness recommended for Rose Pins is 1-2 mm. When choosing a specific model from the range of Rose Pins, you should take into account the thickness of the material and carry out test before each application, to adjust the pressure.

c) Swarovski 3D Studs.

Problems that appear after mechanical application:

- the product is not perfectly attached to the carrier material,

- fabric crinkles,

- crystals break.

- too low or high pressure during application,

- wrong dies used,

- improper position of die,

- product not suitable for material thickness,

- use of an inappropriate back part, regarding type of product and material.

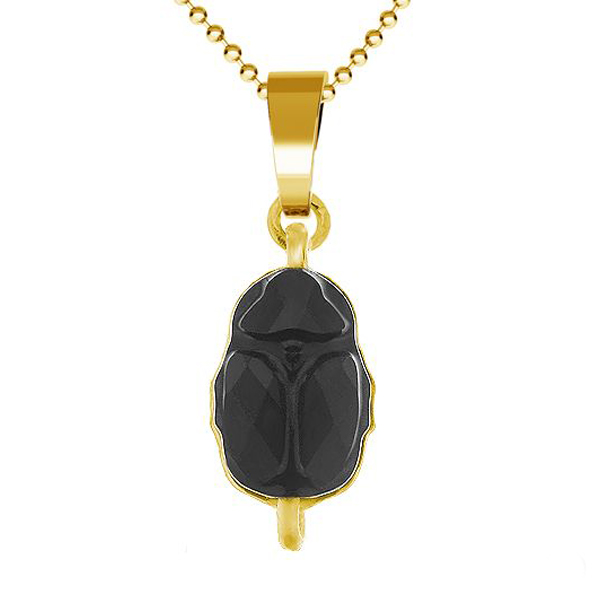

Another method used for applying Swarovski stones is soldering. Silvexcraft offers a wide selection of products for soldering and silver solder, that allow to create jewelry using crystals in a simple and quick way. When soldering, make sure that the components are clean and especially free of grease. Also pay attention to the right amount of solder wire or solder paste, because too much solder can flood the crystal, damaging or discoloring it, while too little — will prevent soldering of the elements. Remove the excess solder as soon as possible, as it will facilitate the polishing process and possible galvanization. When soldering, avoid a sudden drop in temperature, as this may damage the crystal by cracking or chipping. Additionally, it is recommended to use protective clothing, eyewear and gloves, as well as adequate ventilation of the room during application. When soldering ready Swarovski Cupchain products, that have already been integrated into metal settings, use solders with a temperature of up to 280 °C.

The most common problems appearing while soldering are caused by:

- unsuitable solder used — most often due to its melting point,

- too little or too much solder used,

- too long or short exposure to flame,

- inadequate distance between flame and soldered element.

- Xirius Chaton 1088,

- Fancy Stone 4320,

- Cushion Square Fancy Stone 4470,

- Oval Rivoli Fancy Stone 4122,

- Twister Fancy Stone 4485,

- Rivoli Flower Fancy Stone 4744,

- Rivoli Star Fancy Stone 4745,

- Cube Fancy Stone 4841,

- Heart Flat Back 2808,

- Butterfly Flat Back 2854.

The most common problems with crystal deposition are:

- mismatched crystal setting — too small, large, tight, shallow, deep,

- too strong or weak setting claws clamping.

The Swarovski company also offers crystals for sewing, which can be easily applied by hand or with standard domestic sewing machines and industrial sewing or embroidery machines. For sewing crystals, it is worth choosing a strong thread, and in the case of heavier products — a nylon-coated jewelry wire. Synthetic multifilament threads are recommended for sewing crystal buttons and beads, while monofilament yarns and pure cotton should be avoided, due to their limited abrasion resistance.

- The most popular handmade methods include techniques such as:

- knitting,

- crocheting,

- weaving,

- macrame,

- felting,

- beading,

- wire wrapping,

- milling,

- threading,

- settings,

- epoxy resin.

- Beads,

- BeCharmed & Pavé,

- Pearls,

- Pendants.

- Twist 3221,

- Drop 3230,

- Square 3240.

Which surfaces are not suitable for Swarovski crystals?

- Swarovski HotFix crystals are not suitable for application on tightly woven, thin materials such as tulle, smooth leather, leather imitations, waterproof coatings, teflon, silicone, as well as colored with metallic pigments, enzymatically treated and finished with fluorocarbon. In addition, the HotFix application is not used on low-absorbency surfaces — find out how to test in the article: Swarovski FAQ — Part 1.

If it is not possible to use HotFix crystals, ColdFix is recommended, which is most often used on materials sensitive to heat and pressure. Examples include leather, wool, lycra, polyester and various technical materials. - Swarovski No HotFix crystals can be applied to most materials and surfaces, but most important is to choose the right glue.

- Swarovski Mesh can be applied to materials that are suitable for hand or machine sewing, while in case of Crystal Fine Mesh it is recommended only and exclusively hand sewing, because the crystals are placed very close to each other, so there is a risk of damaging the adjacent crystals.

- No Flat Backs are best applied in made-to-measure bases, most often silver or gold, with the use of glue or stone setting method.

- Flat Backs also called cabochons, can be used on most surfaces, but the key issue here is to choose the right glue. When using a UV glue, it is important that at least one of the elements (the crystal or the material that is bonded with the crystal) is transparent, so it can pass the UV rays. Read more about gluing in Swarovski FAQ — Part 1.

Why does the foil rub off the crystals?

What crystals can be applied to underwear?

Why did the crystal change color or became dull?

The most common reason for matting or discoloration of the crystal is the excess of glue, that has been smeared on the crystal surface. Unfortunately, the glue excess is difficult to remove after drying. In some cases, it can be cleaned with the use of nail polish remover and then polishing it with a polishing cloth. Unfortunately, not all adhesives can be removed after drying without damaging the crystal, so to avoid this problem in the future, remove excess adhesive during application, preferably with

a cotton cloth dipped in acetone or isopropyl alcohol. It is also worth getting a dispenser, in order to more accurately measure and glue application.

Why did the crystal fall off without foiling?

There are several reasons, that may cause the crystal to separate from the foil:

- the wrong glue was used, possibly with a high degree of shrinkage, which damaged the foil during setting and caused its adhesion to the crystal to decline,

- the glue gap was not completely filled with glue, so oxygen penetrated between the crystal and the mirror and caused oxidation,

- in case of using two-component glue, the wrong proportions were used, so the glue did not achieve the correct bond strength,

- the adhesive has changed its properties under the influence of contact with unsuitable cleaning agents.

Why did the crystal come off with the foil?

The most common reasons for detachment of the crystal are:

- the use of an inadequate setting, so the bottom of the crystal did not fully adhere to its surface,

- the application surface was dirty or greasy, so the crystal did not obtain adequate adhesion,

- too little glue was used,

- the recommended lifetime with the adhesive was exceeded, therefore it has hardened before it bonded with the crystal,

- the wrong glue was used,

- the glue was stored improperly,

- the end product was used before the glue has fully hardened.

Swarovski pearls – durability and resistance to damage

Swarovski pearls are built on the basis of a patent developed over the years by a team of specialists. They consist of a crystal core covered with several coatings, thanks to which they look and feel like real pearls. Many years of testing and experience have made them resistant to abrasion, scratches, and the influence of external factors such as: UV radiation, perfumes, cosmetics and sweat. Pearls should be wiped occasionally with a soft damp cloth with little mild soap, and then allowed to dry. Avoid polishing cloths, as well as agents containing acetone and solvents, because there is a high risk of dissolving its attractive outer coating. However, it should be remembered, that despite the pearls having a protective coating, they should be treated as any other jewelry, by avoiding or minimizing their contact with cosmetics, detergents and other chemicals, as well as UV rays and moisture. It is also important to store them in containers designed for jewelry. Because Swarovski Pearls meet the highest standards of durability, they are often chosen for jewelry design, decorating textiles and interior decoration. Discover the beauty of them in the article: Swarovski pearls — beauty, durability and innovation.

Swarovski offers a wide selection of top-quality crystals, which has made the company synonymous with authentic crystals. Patents developed and improved over the years, subjected to rigorous quality control, guarantee maximum precision, perfect form and unique brilliance of the products, which is why they have become so widely used in the jewelry, accessories, clothing, footwear and interior decoration segments. In this article we discussed the most popular Swarovski crystals, methods of their application and answered the most frequently asked questions by our customers. If, after reading Part 1, Part 2, and Part 3, you still have questions or concerns regarding Swarovski products, feel free to ask in comments below.

Discover Swarovski history

Find out How to tell if Swarovski crystals are real

If you found this article valuable, we will appreciate it if you comment below and follow us on social media! Have a great day!

Follow us:

Follow us:Instagram:

@jewelry.findings

@jewelry.findingsFacebook:

925CRAFT World

925CRAFT WorldYoutube:

DIY WITH 925CRAFT

DIY WITH 925CRAFTPinterest:

925CRAFT

925CRAFT 925CRAFT (@925craft)

925CRAFT (@925craft)Join to our group of jewelry makers:

Source: Swarovski for Professionals