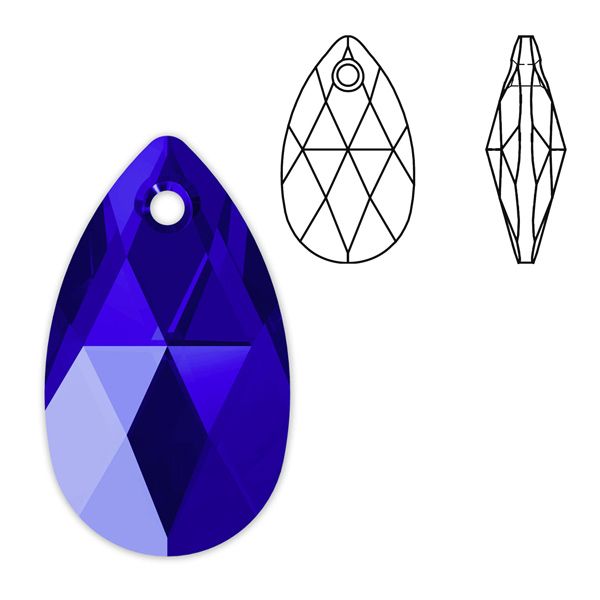

The most popular Swarovski Crystals are:

1. Round Stones, or chatons – round crystals with a pointed underside, considered to be the most innovative rhinestones on the market. Their one-of-a-kind, multi-faceted cut makes them exceptionally radiate and guarantee a unique glow. Round Stones crystals are appreciated by designers all over the world, thanks to which we can admire them on the catwalks, large film productions, as well as dance and music events, in the form of costumes, jewelry, accessories and even décor creations. Examples include some of the most famous international designers like Versace and Jean Paul Gaultier, who regularly used Swarovski crystals in their designs. Crystals are produced in many sizes and with a total of over 100 intensely vibrant colors and effects. The most popular of them is Xirius Chaton 1088 – considered to be the closest to a diamond, Xilion Channel 1128, Xero Chaton 1100 – considered the smallest crystal in the world, often used in tiny decorations on glasses, dials in watches and advertising projects like logos. Very popular are Rivoli 1122, Flat Chaton 1201 and Brilliant Cut 1357 are also very popular. Currently, some Swarovski crystals may not be available on the market, due to the recent transformation of the Swarovski brand business model. Referring to the above and realizing that many of our clients have been making jewelry collections based on silver settings dedicated to specific crystals for years, as an alternative we have introduced new stones to our offer. Swarovski Rivoli 12 mm crystals can be perfectly replaced with GAVBARI RIVOLI semi-precious stones, which have the same shape and are available in a wide range of colors. In our collection you will find a large selection of findings dedicated to these stones, thanks to which you will create phenomenal earrings, pendants, necklaces, rings, bracelets and cufflinks.

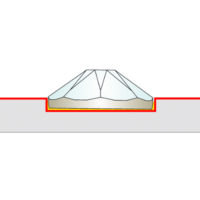

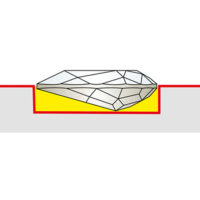

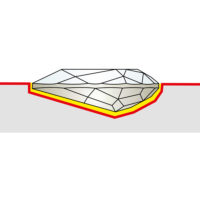

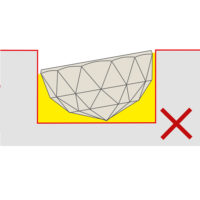

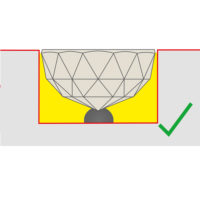

Application of Round Stones: gluing, stone setting and embedding in Ceralun.