- Contact us:

- +48 17 2300 400

- [email protected]

Swarovski FAQ – Part 1

Gold findings for jewelry

September 10, 2020

Swarovski FAQ – Part 2

October 30, 2020Swarovski is an Austrian family business that since 1885 has been producing crystals which stand out by maximum cutting precision, form perfection and marvelous brilliance. Find out more about the brand. Swarovski crystals are made of a combination of quartz, sand and various minerals, which, thanks to the use of specific formulas and cuts developed over the years, obtain the highest quality. Crystals are widely used to make jewelry, accessories, clothing, and they are also popular in interior design. Swarovski offers a wide range of shapes, sizes, colors, effects and application methods. To make it easier to start the adventure with crystals, the company has also developed a multi-page guide that describes in detail all the products, techniques of application and care, but not many people have the time and willingness to familiarize themselves with this extensive encyclopedia, so below we have summarized the most frequently asked questions.

HotFix vs. Non HotFix

Non HotFix crystals have no glue layer attached but are covered with platinum foil for extra shine and protection. Non HotFix can be applied in 3 ways: with glue, with Swarovski Ceralun or with stone setting machine.

HotFix is recommended when applying large amounts of crystals on heat-resistant materials – as this application is faster. However, when applying single or smaller amounts of crystals on temperature-sensitive materials – No HotFix is recommended.

What surfaces for HotFix and Non HotFix?

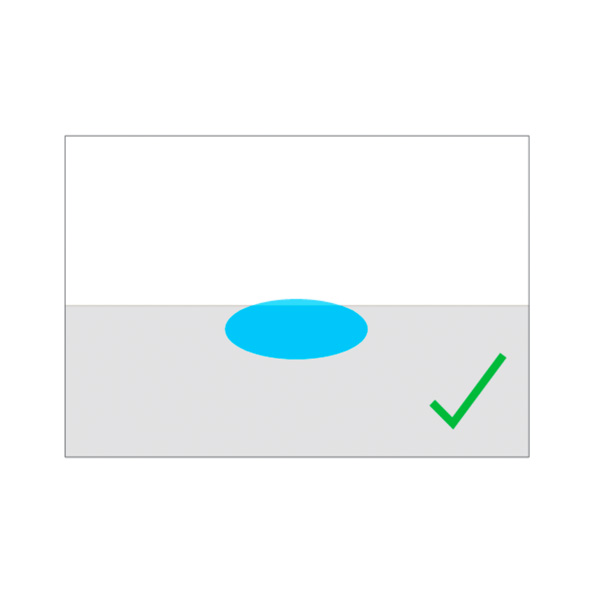

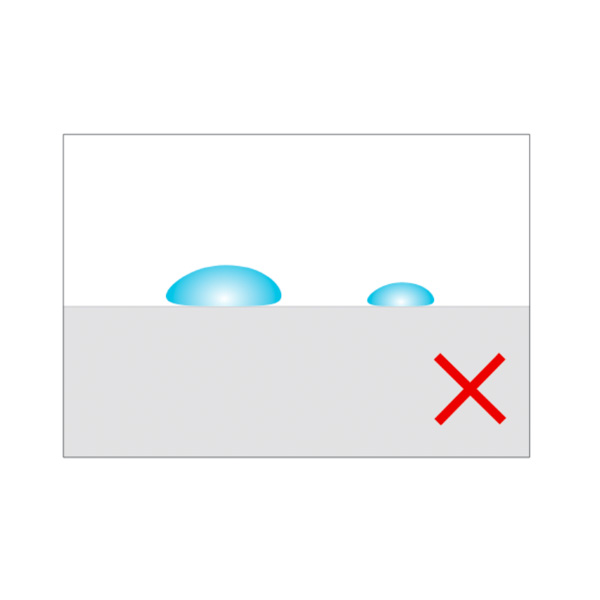

HotFix is used on highly absorbent materials, so before starting the application, a water drop test should be applied. If water soaks into the material quickly, it indicates high absorbency. If water remains on the surface in the form of pearls or soaks very slowly, it means insufficient absorption of the material, which can reduce the effectiveness of HotFix application.

SWAROVSKI TEST

WATER DROP TEST

- tightly woven fabrics,

- very thin fabrics such as tulle,

- smooth leather and smooth leather imitation,

- hydrophobic and waterproof coatings such as: silicone, synthetic resin,

- Teflon coatings,

- stain-resistant coatings,

- fluorocarbon finishes,

- materials after the use of softeners,

- materials colored with metallic pigments,

- enzyme treated coatings.

No HotFix crystals can be used almost on all materials, but the key is to choose a proper glue.

What we need for HotFix application?

- HotFix crystals,

- heat press, ultrasonic device, stone setting machine, HotFix applicator or iron without steam,

- Teflon foil,

- compensating pad: silicone foam, foam rubber or felt,

- cardboard,

- tweezers or a wax stick (e.g. Crystal Katana Tool).

How to apply HotFix?

Several solutions can be applied to the HotFix such as: heat press, ultrasonic device (suitable for products: 2078, 2038, 2716, 2816, 2826), stone setting machine, HotFix applicator (suitable for products: 2078, 2038) or iron without steam. Regardless of the method chosen, when applying HotFix, few factors should be taken into account:

- temperature – the glue is activated at a temperature of 120 to 170 °C – its exact selection depends on the base material and its sensitivity to temperature

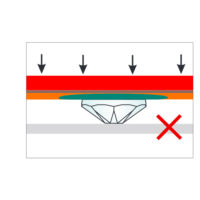

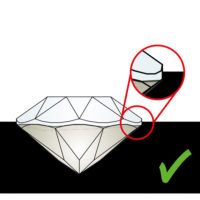

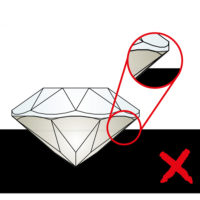

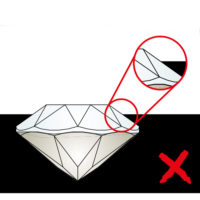

- pressure – depends on the type of applied elements, base material and device chosen. Too much pressure may cause glue to be spread out crystal area, while too little pressure may not bond the crystal to the material properly. In addition to strength, it is also important that the pressure is equable and perpendicular to the surface of the crystals to uniformly bond the crystals and avoid chipping or breaking at the edges,

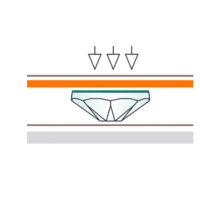

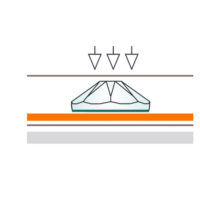

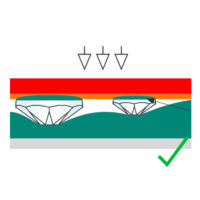

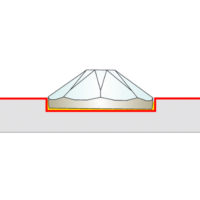

- heating length – depends on the type of crystals, temperature, material and device used. Be careful not to overheat the glue, as there is a risk of spreading it out crystal area and affecting the appearance of material (figure 1-2),

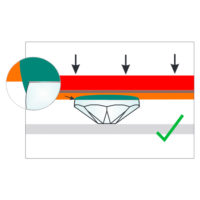

- application side – it is possible to apply from below or above (figure 3-4), however the best is to choose a method whereby the heat reaches a glue as quickly as possible. Some crystals can only be heated from the bottom due to uneven heat transfer (cabochon transfers, creation transfers plus).

For crystals in different sizes, use a compensating pad such as: silicone foam, foam rubber or felt to match the crystals height (figure 5).

THERMAL PRESS:

ULTRASONIC DEVICE:

a pump, alternatively a transfer foil or tweezers may be used.

HOTFIX APPLICATOR:

Using the Swarovski crystal applicator is a cost-effective option. In order to apply, choose an applicator point adapted to the size of the crystal, heat the applicator, pick up the crystal and when the glue dissolves, place the crystal on the base material and press firmly.

IRON:

If you do not have any of the above devices, it is possible to use a domestic iron, but it must be a steam-free one, as water droplets and steam may have a negative effect on the bond between crystals and material. In order to apply with an iron, depending on the type of crystals and the base material, set the temperature of the iron not higher than 150 °C. In order to avoid penetration of the glue into the subsequent layers of the material, it is worth separating them with felt or cardboard, while on the crystals it is worth placing a Teflon foil, to avoid the iron becoming stained with the glue.

Guidelines for temperature and heating time in relation to crystal type and material are available here: Swarovski guidelines, but keep in mind that these values are approximate and it is always recommended carrying out tests before.

What we need for Non HotFix?

- Non HotFix crystals,

- glue,

- a piece of paper and a stick for mixing,

- protective gloves, for example nitrile ones,

- tweezers or a wax stick (e.g. Crystal Katana Tool),

- a glue dispenser if needed,

- optionally a degreasing agent, such as: ethanol, acetone or cleaning solvent.

No HotFix application

When using glue, it is a good idea to test the surface tension for the wetting properties with a test pen (figure 1-3). If the ink remains visible for 2 seconds, the surface is suitable for gluing, if the ink fades faster

or forms bubbles, the surface is not suitable for gluing and should be cleaned, usually with isopropyl alcohol, acetone or cleaning solvent.

When selecting a glue, few factors should be taken into account such as:

- the type of cavities (shape, width and depth in relation to the crystals) or resulting gluing gap,

- type of crystals (foiled or unfoiled),

- size of crystals,

- application area,

- type of base material,

- glue properties (pot life, viscosity, color, curing time, ease of dosing, shrinkage).

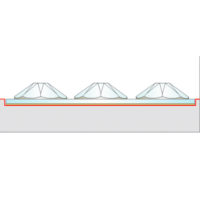

For better connection of crystals with the base material, it is worth using custom-made cavities or dedicated bases (figure 4-5). The cavity facilitates better seating and protection of the crystal against mechanical and chemical factors. They can be made by casting, drilling, milling or water jet cutting.

When applying small crystals in a fitted cavity, it is worth using a strong bonding adhesive, preferably

two part epoxy glue, which has a lower degree of shrinkage and provides greater strength. When deciding on a two-component glue, it is very important to keep the recommended proportions, mix the ingredients until a homogeneous consistency and not to exceed the recommended pot life.

Regardless of which glue you choose, remove its excess before it hardens with a cotton cloth dipped in a solvent containing isopropyl alcohol. If the glue hardens, it is unlikely to be removed without damaging the crystal surface.

HotFix and No HotFix care

Ceralun

What we need for Swarovski Ceralun?

- Ceralun,

- knife and pad,

- jewelry scale,

- protective gloves, e.g. nitrile ones,

- protective eyewear,

- a wax stick or Crystal Katana Tool, alternatively tweezers,

- possibly a sieve for crystals.

How to apply Swarovski Ceralun?

2. Cut the appropriate amount of resin and hardener, usually in a 1: 1 ratio by weight, and check their exact weight with jewelry scale.

3. Mix them together until you get a homogeneous appearance – the ingredients come in different colors, making it easier to recognize when they have been properly mixed together.

24 hours, however, when defrosting, make sure to get rid of any water generated. Once the Ceralun reaches the lukewarm temperature, you can proceed with setting the crystals.

When placing the crystals in the Ceralun mass, make sure that it is sunk perpendicularly to the correct depth.

Ceralun is available in 17 shades, but if you need less standard colors, you can mix the basic ones. However, it is important to mix epoxy resin and hardener of each color before you mix them together.

Why does Ceralun not harden or the crystals become detached?

- inappropriate area of the application (see the marker test in HotFix section),

- wrong mixing ratio,

- too short time of mixing the ingredients with each other, before homogenous appearance is achieved,

- in the case of storing mixed Ceralun in a freezer, the time exceeded 24 hours or the temperature was significantly different from -20 °C.

Swarovski Crystal Mesh

What we need for Crystal Mesh?

- Crystal Mesh,

- sewing machine, domestic or industrial, depending on the needs,

- needles, sewing threads (monofilament and pure cotton yarn is not recommended due to their limited abrasion resistance),

- sharp scissors,

- possibly a height compensator (silicone or rubber foam).

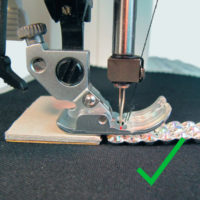

How to apply Crystal Mesh No HotFix?

2. After cutting the film, there appears some space between the crystal rows, which makes it easier to separate them.

5. Adjust the needle and thread and set the appropriate thread tension.

When sewing tall, multi-row elements, problems with the feed of the sewing machine may occur due to the slanting presser foot. To avoid this, position height compensator beneath the presser foot, so it lies flat on the fabric, allowing it to run easily and smoothly.

Crystal Mesh care

Find out How to check if Swarovski crystals are real?

If you found this article valuable, we would be grateful if you like, share with others, or comment, which will be an energy booster for us to write more articles! Thanks and Have a Nice Day!

Instagram:

Facebook:

Youtube:

Pinterest:

Tik Tok:

Join our group of jewelry makers:

Related posts

Cube beads with letters for jewellery making

How to Make Charm Bracelets and Bead Bracelets

How to make jewelry for communion

How to make string bracelets – a guide for jewelry makers from 925CRAFT

Infinity bracelets and clover bracelets – how to make bracelets with symbols

Jewelry trends for winter 2023

Wholesaler of natural stones for making jewelry – 925CRAFT

How to start a jewelry business – a guide for beginners

How to use silver hoop earring findings – part 1

2 Comments

I have 700 to 1000 pearls to sell….I’m reasonable I need the money

Thank u in advance

Hi,

I’m not sure how we can help,

best to try to sell them on platform such as ebay, or publish it on Facebook jewelry makers groups,

regards 🙂